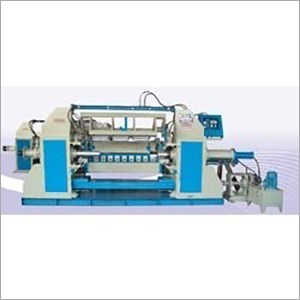

Rotary Log Peeling Machine

Product Details:

- Product Type Rotary Log Peeling Machine

- Machine Type Woodworking Machinery

- Machine Style Horizontal

- Capacity 8-10 Logs/Hour

- Voltage 380-440 V

- Power 32 kW

- Automation Automatic

X

Rotary Log Peeling Machine Price And Quantity

- 1 Unit

Rotary Log Peeling Machine Product Specifications

- 5800 x 2200 x 1700 mm

- 32 kW

- Woodworking Machinery

- 4800 kg

- Automatic

- Horizontal

- 8-10 Logs/Hour

- Rotary Log Peeling Machine

- Industrial Blue/Grey

- 380-440 V

- Heavy Duty Induction Motor

- 0-80 m/min

Rotary Log Peeling Machine Trade Information

- Yamuna Nagar

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Cash Advance (CA), Cash in Advance (CID), Cheque

- Per Day

- 15 Days

- Australia, Central America, South America, Western Europe, Middle East, Eastern Europe, Asia, North America, Africa

- South India

Product Description

Technical Specification

| Main Motor | 30 H.P. 1440 RPM |

| Compressors Motor | 3 H.P. 1440 RPM |

| Power Pack | Fitted with POLYHYDRON Valves & 5 HP Motor |

| Electrical Panel | Fitted with L & T or ABB Switches |

| Brake | Imported Three Stage Disc Brakes for long life |

| Can Peel | 0.6 mm to 3 mm |

High-Capacity Woodworking Performance

This machine processes 8-10 logs per hour, making it ideal for industrial-scale production. The gear chuck ensures firm grip and precision during operation, while the heavy-duty cast iron frame provides durability under rigorous conditions. Its horizontal style and large dimensions accommodate sizable logs for efficient peeling in factories and plants.

Advanced Control & Automation

Equipped with a PLC system, the rotary log peeling machine promotes accuracy and convenience. Automatic knife angle and depth settings streamline the peeling process, minimizing downtime and maximizing output. The integrated hydraulic and air-cooled systems maintain operational stability during prolonged use.

Enhanced Safety & Noise Reduction

Operator safety is prioritized through emergency stop functions, overload protection, and comprehensive safety covers. The machine operates at noise levels below 85 dB, contributing to a safer and quieter working environment without sacrificing performance.

FAQs of Rotary Log Peeling Machine:

Q: How does the Rotary Log Peeling Machine ensure accurate veneer thickness during operation?

A: The machine uses a PLC-controlled system combined with automatic knife angle and depth adjustments to maintain precise veneer thickness within the range of 0.5 mm to 4 mm, ensuring consistency and reducing material waste.Q: What types of wood products can be produced with this log peeling machine?

A: It is primarily used for manufacturing plywood, veneer, and various wood panels, supporting both mid- and large-scale production needs in woodworking industries.Q: When should the machines safety features be utilized during operation?

A: Safety features such as the emergency stop, overload protection, and safety covers should always be engaged during operation and especially in case of an emergency or equipment irregularity to prevent accidents.Q: Where is this rotary log peeling machine manufactured and distributed?

A: The machine is manufactured in India and is available to dealers, distributors, exporters, and wholesalers throughout the region for both domestic and international supply.Q: What is the process for adjusting the peeling blade on this machine?

A: Blade adjustments are handled automatically by the system, which sets the knife angle and depth according to the selected parameters, simplifying setup and ensuring optimal peeling quality.Q: How does the integrated hydraulic and cooling systems benefit machine usage?

A: The high-efficiency hydraulic unit enables stable and powerful log handling, while the air-cooled system prevents overheating, thus maintaining smooth, continuous operations without frequent intervention.Q: What are the key advantages of using this rotary peeling machine for high-volume production?

A: Key benefits include fast processing speed (8-10 logs/hour), robust construction for longevity, reduced manual intervention thanks to automation, enhanced safety, low noise levels, and consistent product quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Log Peeling Machine' category

|

JAMUNA ENGINEERING COMPANY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |