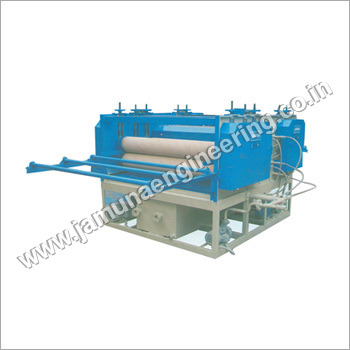

Plywood Making Machines

Product Details:

- Type Plywood Making Machines

- Material Iron

- Capacity 1500 - 2000 Piece/Day

- Computerized No

- Automatic Grade Semi-Automatic

- Power 7.5 HP

- Voltage 380 V

X

Plywood Making Machines Price And Quantity

- 1 Unit

Plywood Making Machines Product Specifications

- No

- 4200 mm x 2500 mm x 1800 mm

- Iron

- Semi-Automatic

- 1500 - 2000 Piece/Day

- 380 V

- Blue & Grey

- Approx. 3500 kg

- 7.5 HP

- 6-8 kg/cm

- Plywood Making Machines

Plywood Making Machines Trade Information

- Per Day

- Days

- All India

Product Description

Our cutting edge technology facilitates in the fabrication of a world class gamut of Plywood Section including Plywood Making Machines, Log Peeling Lathe Machine, Spindle Less Rotary Peeling Lathe, Log Peeling Lathe Machine, Veneer Dryer and others. These are available in different specifications such as length, diameter, thickness etcEfficient Sheet Processing for Plywood Industries

Experience optimized industrial plywood manufacturing with our semi-automatic machines, engineered to peel, cut, and stack sheets precisely. Their robust design ensures consistent performance for large-scale operations while maintaining processing accuracy even with varying sheet sizes and thicknesses. Ideal for businesses seeking higher throughput and reliability.

Adaptable Control and Power System

Utilizing a manual/relay control system, these machines offer adaptability for diverse production environments. Powered by a vigorous 7.5 HP motor within a three-phase configuration, they provide equilibrium between high-capacity output and energy efficiency. Their computer-free operation assures simple maintenance and user-friendly operation.

Durability and User Safety Emphasized

Built with high-quality iron and coated with durable paint, the machines are engineered to withstand demanding industrial use. The thoughtfully selected blue and grey colors not only offer an elegant look but also enhance workplace aesthetics. Standard air pressure requirements and weight specifications ensure smooth function and workplace safety.

FAQs of Plywood Making Machines:

Q: How does this plywood making machine enhance industrial production efficiency?

A: This machine is designed for semi-automatic operation, enabling efficient peeling, cutting, and stacking of plywood sheets reducing manual labor, increasing output rates to 1,5002,000 pieces per day, and ensuring consistent quality across batches.Q: What processes can be performed by the plywood making machine?

A: The machine is capable of peeling, cutting, and stacking sheets. It supports sheets up to 2,600 mm wide and as thin as 0.3 mm, accommodating diverse plywood manufacturing requirements.Q: Where is this plywood making machine typically used?

A: It is intended for industrial plywood manufacturing factories and units, with applications suitable for manufacturers, dealers, wholesalers, exporters, and distributors in India.Q: When should maintenance be performed on the machine and what does it involve?

A: Regular maintenance is recommended based on usage intensity. Key tasks include inspecting mechanical components, ensuring proper lubrication of moving parts, verifying air pressure (68 kg/cm), and maintaining the integrity of the iron frame and paint coating.Q: What are the benefits of choosing a semi-automatic plywood making machine over fully manual models?

A: Semi-automatic models balance production speed and operator control while minimizing the risk of human error. They offer higher capacity, safer operation, and easier process management compared to manual machines.Q: How is the machine powered and what control system does it use?

A: It operates on a three-phase electric supply (380 V, 50 Hz) using a 7.5 HP motor and runs on a manual/relay control system for straightforward operation without the need for computerization.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plywood Machinery' category

|

JAMUNA ENGINEERING COMPANY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |